The Plan-Do-Check-Act (PDCA) Cycle, developed by W. Edwards Deming, provides a simple and effective means to create a virtuous cycle in an organization. It can help you to structure initiatives to solve problems and seize opportunities.

This post looks at what the PDCA cycle is, dives into the specifics of the four steps, looks at pros and cons, and enumerates where it can enhance strategy and project management efforts.

What Is the PDCA Cycle?

The Plan-Do-Check-Act (PDCA) process or method was developed by William Edwards Deming, one of the prime creators of the quality movement. PDCA is considered to be a part of the quality movement – but it is also a method associated with change management.

The idea of the PDCA method is to continuously improve products, services, and processes. The end goal is to improve quality and decrease costs by iterating multiple times through the process.

Here is a brief explanation of each of the fours steps of the PDCA method:

- Plan – Plan to seize an opportunity, anchored by a hypothesis with expected results.

- Do – Execute the plan in a small scale test, and generate relevant performance data.

- Check – Compare the performance data against the expected results, and analyze.

- Act – Based on results, implement improvements, and adjust based on shortcomings.

The PDCA method can be applied to every area of the business model. A multi-dimensional approach to initiatives across the business model can provide geometric improvements in the business.

The PDCA model has also been known as PDSA (Plan-Do-Study-Act), the Deming cycle, Shewhart cycle, and earlier Plan-Do-See. This post sticks with ‘PDCA’ – so let’s go a little deeper into each of the four steps.

Step 1 – Plan

The first step, Plan, involves the following:

The first step, Plan, involves the following:

- Identify subject issue – It can be either a problem or an opportunity. The Plan needs to be well-structured with clear metrics for desired results.

- Understand the situation – The current situation will usually have a number of elements. Be careful to manage the scope of the subject issue while maintaining the perspective of how it fits with the entire situation.

- List potential solutions – Try to exhaust the list of possible solutions with the team, as this can produce some creative ideas. You may need to dive deeper into some for everyone to fully grasp them.

- Select the best solution – Identify the best solution based on cost, impact, risk, timing, and other relevant factors. Ensure that you pick and define something that is clearly measurable.

This one best solution becomes the basis for your hypothesis. What problem do you expect this solution to solve? What metrics can you use to measure whether it solves the problem? What are your expected metrics?

Identifying gaps can be a great way to get started with the Planning process. It can be a way to start asking questions and generating ideas.

Step 2 – Do

Here you begin to put the idea into action – to see if it validates your hypothesis. The following actions are part of the ‘Do’ step:

Here you begin to put the idea into action – to see if it validates your hypothesis. The following actions are part of the ‘Do’ step:

- Follow the plan – Keep an open mind to further clarifying the problem in this step. Tweak as necessary in order to execute effectively. But execute the Plan to generate the data to validate – or invalidate – the expected results based on your hypothesis.

- Take action – Keep it low cost and on a small scale to facilitate open-mindedness. This is an experiment at this point. Verify that the problem or opportunity is what you think it is. This can provide needed flexibility.

- Observe – Collect the data – both by documenting visual observations and by assembling performance metrics. Try to format the data so that it can easily be compared to your expected results and observations – and can be presented to other stakeholders.

PDCA is action-oriented. It is meant to be an optimal blend of thinking and acting.

Step 3 – Check

You can begin to get some payback in this step. It continues to put the scientific method into practice.

You can begin to get some payback in this step. It continues to put the scientific method into practice.

- Actual vs expected – Compare your actual results to your expected results. If you have planned correctly, they should map to one another and be easy to compare.

- Analyze the data – Add some perspective to the data by performing analysis. What statistics could provide valuable insights? Performing statistical analysis, charting or preparing visuals of the data, and answering some specific questions are a good approach for this.

- Lessons learned – What did you learn from the checking of the data? Did you run into any unexpected issues? Is the data valid? What conclusions can you draw, and what is your confidence in those conclusions? How can you better structure and execute your approach the next time to get more impactful and reliable results?

Note that Deming actually placed more emphasis on studying the data vs checking it. That’s why PDCA is sometimes referenced as PDSA – Plan-Do-Study-Act. Studying implies deeper thinking and inferring more meaning from the results. Deming emphasized Study as more appropriate – hence, PDSA.

Also, note that the implemented solution may not have generated definitive results. You may want to sketch your thoughts on a flow chart, showing what to do with definitive Yes-No results, or you may need to tweak your execution and go back to step 2.

Step 4 – Act

In the final step, you move ahead based on what you have learned. Here are the key elements of the ‘Act’ step:

- Implement – It the outcome warrants it, integrate it fully into the existing framework. If it does not, discard it. In either case, document what you learned and some ideas for future iterations through the process for further improvements.

- Reset – Establish the new baseline, if there is one, as the new normal. Take your Lessons Learned as an input to the next Plan cycle. Here you are formalizing in your gains.

- Sustain – Establishing a ‘new normal’ entails putting supporting pieces in place. That could be some structural components in the organization located around the change, re-education of people, or changed support routines. Beyond formalizing, this step locks in the gains.

Having been through all four steps, you want to leave this cycle with the beginnings of a plan for another iteration of the PDCA cycle.

Strategy and PDCA

Part of strategy is determining how an organization will build competitive advantage in a continuous upward path, improving continuously toward the strategic objectives. PDCA can especially help to accomplish two strategic objectives:

- Improve quality

- Decrease costs

The diagram at right shows how PDCA itself is a continuous process consisting of multiple cycles, or iterations, through Planning, Doing, Checking, and Acting. The goal of these continuing cycles is to continuously improve along the dimensions of quality and cost.

Quality advantages can drive a strategy of differentiation. Cost advantages can drive a strategy toward being a low cost producer through economies of scale and scope. Or, a hybrid of cost and quality advantage can be achieved through a mass customization strategy. The graph shows a virtuous cycle of improving quality and decreasing costs that is important for any organization.

These virtuous cycles need to be placed in the right areas – strategically – and adjusted if needed. The whole process of implementing strategic initiatives can be placed into a PDCA cycle. The idea here is that strategy itself can be structured into a PDCA cycle, and there can be more localized initiatives within that framework that will have their own PDCA cycles. This nesting idea is illuminated in “The Deming Cycle” by Paul Arveson of the Balanced Scorecard Institute (BSI).

—————————————-

I recommend these strategy resources on FlevyPro (paid links):

| Change Management Frameworks Reference Guide 402-slide PowerPoint deck $179.00 |

Change Management Models 136-slide PowerPoint deck $59.00 |

|

|

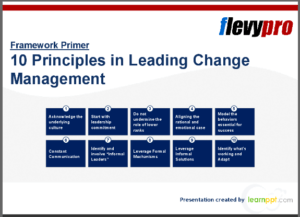

| 10 Principles in Leading Change Management 17-slide PowerPoint deck $25.00 |

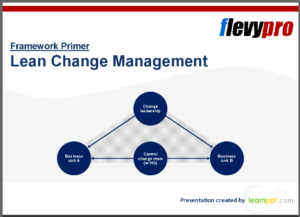

Lean Change Management 21-slide PowerPoint deck $25.00 |

|

|

—————————————-

Project Management and PDCA

You can use the PDCA method in the practice of project management in a number of ways. Here are some examples:

—————————————-

I recommend these PM templates (paid link):

—————————————-

- Source of continuous improvement projects – In portfolio management, you can tap a continuous source of projects when PDCA is used within the organization. Michael Porter identified two types of projects: best practices and innovation-driven. The stream of projects from the PDCA process will mostly be best practices, or continuous improvement, projects. However, PDCA can add value to innovation projects also.

- Program management – When managing programs, delivering value often includes a ‘hardening process’. This is a process of continuous improvement within the scope of the program that works out the bugs and tweaks the quality of the product. This is a perfect place to apply PDCA.

- Project management processes – At the Project Management Office (PMO) level, there are processes used in the management of projects across the organization. PDCA can be a great approach to continuously improving these processes and continuously improving the delivery of projects as an organizational competency.

This is only scratching the surface of possibilities. PDCA can add value to projects and across organizations with a little imagination and a commitment to execution.

Pros and Cons of PDCA – or benefits?

Here are some pros and cons to using PDCA in your organization.

Here are some pros and cons to using PDCA in your organization.

Pros:

- Supports continuous improvement – PDCA is an ideal method for achieving cost reduction and quality improvement initiatives.

- Highly flexible – PDCA can be applied in just about any function in any type of organization. It is a generic, versatile method.

- Simple – As a 4-step process, PDCA is simple to understand and put into action. But it can have a strong impact especially if applied strategically.

Cons:

- Oriented to best practices – PDCA is primarily oriented to best practices, and not necessarily innovation. Spearheading innovation, however, may benefit from applying PDCA in select areas. First, the idea of testing hypotheses is very much a part of the innovation process and is core to PDCA. Second, as innovation work matures, the PDCA method can help to enhance outcomes.

- Requires commitment from leadership – Ongoing support and commitment to continuous improvement as a priority is required. People need to hear that message as part of the culture of the organization. This is only a con because commitment does have a cost. Make the commitment if the benefits justify it.

Using PDCA requires some commitment, but there are strong benefits to using it. Identify those specific benefits for your organization.

W. Edwards Deming and the PDCA Cycle – Conclusion and Further Resources

The Plan-Do-Check-Act (PDCA) Cycle – the W. Edwards Deming PDCA Cycle – can help to structure initiatives to solve problems and seize opportunities. As such, it is broadly applicable to both strategy and project management.

I recommend the following ‘program management’ perspective video, “PDCA Cycle Explained (Deming Cycle | Shewhart Cycle | PDSA)”, by Expert Program Management (EPM):

Thanks for this article! It breaks down the parts of PDCA and has some great points. I see that you mentioned Dr. Deming wanted folks to focus more on “Study” instead of “Check” which is absolutely correct – Dr. Deming never advocated for (or devised) PDCA. The really critical piece of his PDSA cycle is *prediction* and the theory upon which the prediction is based. PDCA, on the other hand, focuses on doing something new/different and checking to see if it works – the focus isn’t on learning and adjusting the theory. If you’re interested, there’s more about PDSA here: https://deming.org/explore/pdsa/.

Christina, thank you so much for your comment. I appreciate you coming in from deming.org – thank you for the link and for pointing out the differentiation between PDCA and PDSA. I thought ‘study’ vs ‘check’ was important, but was not aware of the distinction between predicting and just seeing if something works. I am not quite clear on that, as I understand PDCA to be hypothesis driven. I will check out the reference.